Difference between tempered and laminated glass: Key Car Safety Insights

Learn the difference between tempered and laminated glass for vehicles: how each performs, where it's used, and repair implications.

Jan 22, 2026

generated

tempered vs laminated glass, automotive glass, windshield safety, auto glass types, car window replacement

At first glance, tempered and laminated glass might seem similar, but how they behave under stress is a world apart. The key difference is how they break. Tempered glass is designed to shatter completely into small, dull-edged, pebble-like pieces. Laminated glass, however, is built to stay in one piece, cracking in a spider-web pattern but held together by a tough inner layer.

This fundamental distinction is why one is used for your car's windshield and the other for its side windows. It's a deliberate engineering choice rooted in decades of safety research.

Decoding Automotive Safety Glass

Getting to know the difference between these two types of safety glass isn't just for mechanics or glass technicians. For any vehicle owner, this knowledge is critical. It directly impacts passenger safety in a crash, the security of your vehicle, and how you approach repairs. While both are much stronger than the glass in your home, they are engineered for very different jobs on your car.

How They're Made Matters

The manufacturing process is what gives each type of glass its unique safety features.

Tempered glass starts as a single sheet of standard glass. It’s put through a furnace and then rapidly cooled in a process called "quenching." This creates immense tension in the core of the glass with a high-compression outer layer, making it about four to five times stronger than it was before. This internal stress is also why it shatters into tiny pieces when it breaks—the stored energy is released all at once.

Laminated glass is more of a high-tech sandwich. It’s made by bonding a tough, flexible plastic interlayer, usually Polyvinyl Butyral (PVB), between two layers of glass. This composite structure is what allows it to absorb the energy of an impact and keep the glass fragments glued in place, preventing dangerous shards from flying into the cabin.

The PVB interlayer in laminated glass isn't just for safety. It also does a fantastic job of blocking up to 99% of the sun's harmful UV rays and provides excellent sound insulation, making for a quieter, more comfortable ride.

Key Differences at a Glance

To make it simple, here’s a quick rundown of the most important distinctions between the two. This table breaks down how each glass type is suited for different roles in your vehicle.

Attribute | Tempered Glass | Laminated Glass |

|---|---|---|

Breakage Pattern | Shatters into small, blunt granules | Cracks in a spider-web pattern; stays intact |

Primary Use | Side windows, rear windows, sunroofs | Windshields (federally mandated) |

Repairability | Must be fully replaced if damaged | Minor chips and cracks can often be repaired |

Manufacturing | Thermal tempering (heat & rapid cooling) | Layering glass with a PVB plastic interlayer |

Security | Easier to break through for entry/exit | Significantly more difficult to penetrate |

With this foundation, you can better understand why specific glass is used in specific places on your car. The choice isn't arbitrary; it’s a carefully considered decision based on real-world situations, from collisions to attempted break-ins. Every piece of glass on your vehicle is part of a complex safety system designed to protect you on the road.

How Automotive Safety Glass Is Manufactured

The way tempered and laminated glass perform so differently in an accident isn't magic—it's all in the manufacturing. Each type of glass undergoes a highly specific process that builds in its unique safety features. These methods are what make one perfect for your car's side windows and the other essential for the windshield. Once you understand how they're made, it's easy to see why they're used where they are.

The transformation from a basic sheet of annealed glass into a crucial piece of your car's safety equipment involves intense heat, precise cooling, and sophisticated materials. It’s this industrial alchemy that turns something fragile into a protective barrier.

The Thermal Tempering Process: Creating Strength Through Stress

Tempered glass gets its toughness from an intense thermal treatment. The process starts with a standard pane of glass, which is first cut to the exact shape needed for a side or rear car window.

From there, it goes into a special furnace and is heated to over 1,100 degrees Fahrenheit, hot enough to soften it but not melt it. The real magic happens in the next step, a process called "quenching." The glass is hit with blasts of cool air from high-pressure jets.

This rapid cooling makes the outer surfaces of the glass harden and shrink almost immediately, while the inside cools down much more slowly. This creates a powerful tension in the core of the glass, with a highly compressed layer on the outside.

This internal stress is precisely what makes tempered glass so strong—about four to five times stronger than regular glass. But it's also why it shatters so uniquely. When something breaks that outer compression layer, all that stored energy is released instantly, causing the entire pane to explode into those small, blunt, pebble-like pieces.

The Layered Construction of Laminated Glass

Making laminated glass is less about heat-treating and more about building a high-tech sandwich. This multi-layered approach is all about absorbing impacts and keeping shattered pieces contained. The process is meticulous.

Preparation: It starts with two identical pieces of glass, cut and thoroughly cleaned to form a perfect pair for the windshield.

Interlayer Placement: A thin sheet of Polyvinyl Butyral (PVB), a durable and flexible plastic, is placed between the two glass panes. This PVB layer is the key to the glass's safety performance.

Initial Fusing: The three layers are run through a process that squeezes out any air bubbles and then gently heated. This creates a temporary bond that holds the sandwich together for the final step.

Autoclave Treatment: The assembly is then put into an autoclave—basically, a high-tech pressure cooker. Here, a combination of high heat and immense pressure permanently fuses the glass and PVB into a single, optically clear, and incredibly resilient unit.

This layered construction is the reason a windshield cracks in a spider-web pattern instead of shattering. The PVB interlayer does the heavy lifting, absorbing the force of an impact while holding the broken glass fragments firmly in place. This fundamental difference also changes the repair approach; understanding how to replace a car window glass is a lot simpler when you realize a shattered side window is a completely different job than a cracked windshield.

Analyzing Safety Performance in Real-World Scenarios

Knowing how tempered and laminated glass are made is one thing, but the real test is how they hold up when things go wrong. In a collision, rollover, or even a break-in attempt, the differences between these two types of glass become incredibly clear. Each one is engineered to react to an impact in a very specific, and very different, way.

This isn't by accident. These behaviors are the result of decades of safety research focused on protecting people inside a vehicle. Your car's glass is a core part of its safety system, and how it performs is tailored precisely to where it's located on the vehicle.

Performance During a Collision

In a head-on crash, the windshield does a lot more than just block the wind. As laminated glass, it's designed to absorb a huge amount of impact energy. It flexes and cracks in a characteristic spider-web pattern, but it doesn't fly apart. This serves two critical safety functions.

First, it stops the windshield from shattering into razor-sharp shards that could seriously injure the driver and passengers. Just as importantly, it helps keep everyone inside the car. Being ejected from a vehicle is a leading cause of death in accidents, and the laminated windshield acts as a crucial barrier.

Tempered glass, used for your side and rear windows, has the opposite job. When it takes a hard hit, it's designed to instantly break into thousands of small, pebble-like pieces with duller edges. This design prevents the large, jagged shards of glass that could cause deep cuts in a side-impact collision.

Key Takeaway: Laminated glass acts as a protective shield, absorbing impact and keeping occupants inside the car. Tempered glass provides an escape route by disintegrating into small, relatively harmless granules, minimizing the risk of severe cuts.

This functional difference shapes the entire automotive glass industry. While tempered glass held a commanding 45.3% market share in 2023 because it's on almost every side and rear window, laminated glass is the federally mandated standard for windshields. Its unique PVB interlayer not only provides strength but can also block up to 99% of UV radiation, adding a layer of comfort and health protection. You can read more about the trends in the automotive glass market.

Security Against Break-Ins and Thefts

When it comes to stopping a thief, the difference between the two glass types is night and day. Tempered glass, by its very design, is vulnerable. A single, sharp blow from a pointed tool is all it takes to make the entire window shatter and fall away.

This is what makes "smash-and-grab" thefts so quick and easy. While this quality is great for an emergency escape, it’s a major security weakness.

Laminated glass, on the other hand, is a thief’s worst nightmare. The tough, plastic interlayer holds all the broken pieces together, even after the glass is smashed. A criminal would have to hit the window over and over again in the same spot just to create a small opening. It’s loud, it takes time, and it draws a lot of attention—often enough to make them give up and move on.

Rollover Protection and Structural Integrity

In a rollover accident, a vehicle’s roof is put under immense pressure. The windshield is actually a key structural component that helps maintain the integrity of the cabin.

Because laminated glass stays in one piece within its frame even when shattered, it helps support the roof and prevent it from caving in on the occupants. This is a critical safety feature that tempered glass simply can't offer. Once a tempered side window is gone, it provides zero structural support.

Recognizing these benefits, a growing number of automakers are now offering laminated glass as an option for side windows, especially on luxury and high-end models. This upgrade offers several key advantages:

Enhanced Security: Makes the vehicle significantly harder to break into.

Improved Rollover Safety: Adds crucial structural support along the sides.

Superior Acoustics: The PVB layer is a fantastic sound dampener, resulting in a much quieter ride.

While a laminated windshield is designed to crack under stress, those cracks aren't always a death sentence for the glass. Depending on the specifics, a repair might be possible. You can explore the different types of windshield damage to get a better idea of what can be fixed versus what requires a full replacement.

Where Each Glass Type Is Used on Your Vehicle

The specific glass used in different parts of your car isn't an accident. It's a deliberate engineering choice, guided by strict federal safety regulations and the hard lessons of physics. Each type of glass has a distinct job to do, all centered on protecting you and your passengers.

Your windshield is exclusively made from laminated glass. This isn't just a preference; it's a legal requirement. In a crash, the windshield does far more than just keep the wind out—it's a critical component of your car's structural integrity, helping to keep the roof from collapsing in a rollover and ensuring your airbags deploy correctly.

The key is that laminated glass holds together on impact. Its vinyl interlayer prevents it from shattering into pieces, creating a powerful safety barrier that stops occupants from being ejected from the vehicle, which is a major cause of fatalities in accidents.

Side Windows, Rear Windows, and Sunroofs

Once you move away from the windshield, you'll almost always find tempered glass. This is the standard for side windows, the rear windshield (often called the backlite), and sunroofs. The reasoning here is all about its unique breaking pattern.

If you're in an accident where the doors become jammed, a tempered glass window needs to be breakable for an emergency escape. Because it crumbles into small, pebble-like pieces, the risk of getting seriously cut by massive, jagged shards is drastically reduced. It’s the perfect choice for areas where getting out is just as important as staying in.

Situational Logic: Laminated glass is for keeping you in the car during a frontal impact. Tempered glass is for letting you out of the car in other emergencies while reducing the risk of severe cuts.

This standard layout strikes a smart balance between safety, weight, and cost. Tempered glass is lighter and cheaper to manufacture, making it a sensible and safe solution for most of a vehicle's glass surfaces.

A Growing Trend in Premium Vehicles

While that's the standard setup, things are starting to change, especially in the luxury market. You'll now find many high-end vehicles offering laminated side windows, either as a standard feature or a premium upgrade.

Why the shift? It comes down to two things: comfort and security. The plastic layer inside laminated glass is a fantastic sound dampener, cutting down on wind and road noise to create a much quieter ride. It also makes the car significantly harder to break into—a thief can't just smash the window and grab what's inside.

This trend underscores the evolving uses for different glass types. A hybrid known as tempered laminated glass actually holds the largest share in the global laminated glass market, which shows how manufacturers are blending strength and safety. As the market is projected to grow from USD 20.37 billion in 2024 to USD 29.0 billion by 2035, understanding these differences becomes even more critical for car owners. You can explore more about the global laminated glass market growth to see where the industry is heading.

Repair vs. Replacement: What to Do When Your Auto Glass Is Damaged

You’re driving along, and then you see it—a chip or a crack in your car’s glass. The immediate question is always the same: can this be fixed, or am I looking at a full replacement? The answer comes down to one thing: the type of glass that took the hit.

Knowing the fundamental difference between tempered and laminated glass is what separates a quick, inexpensive fix from a more involved replacement.

For tempered glass, the rule is cut and dry. This glass is engineered to shatter into tiny, relatively harmless pieces on impact. If your side window, rear window, or sunroof is damaged in any way, a repair is completely off the table. A full replacement is the only safe and viable option.

Laminated glass, on the other hand, is a different beast entirely. That tough plastic interlayer holding your windshield together doesn't just prevent shattering—it also makes repairs possible.

When Can You Repair a Windshield?

A windshield repair is a great option when the damage is small and doesn't sit right in your line of sight. A skilled technician can inject a special resin into the damaged area, which hardens to restore the glass's structural integrity and much of its original clarity.

Generally, you’re a good candidate for a repair if the damage fits these guidelines:

Chip Size: The impact chip is no bigger than a quarter.

Crack Length: You're dealing with a single crack that's shorter than six inches.

Location: The damage is not in the driver's direct line of sight or too close to the edge of the windshield.

Choosing a repair isn’t just about saving money; it’s also much faster. Most chip repairs are done in less than 30 minutes, getting you back on the road in no time.

A Word From the Experts: Don't put off fixing a small chip. Everyday driving—from road vibrations to temperature swings—can cause that tiny flaw to spread across your windshield. What could have been a simple repair quickly becomes a mandatory replacement.

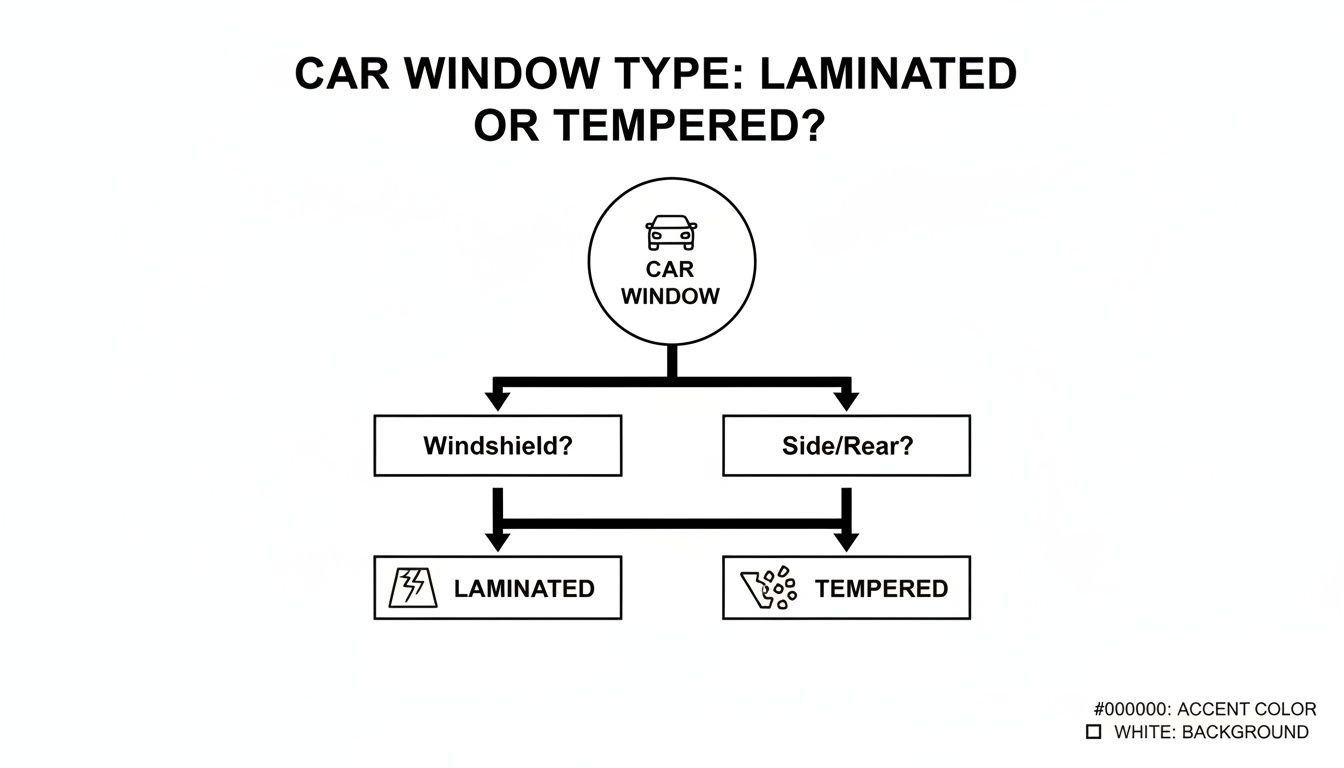

This flowchart clearly shows where each type of glass is typically used, making the repair-or-replace decision much simpler.

As you can see, an issue with a side or rear window means a replacement is in your future. A damaged windshield, however, gives you options.

When Replacement Is the Only Safe Choice

While repairs are convenient, safety is paramount. A full windshield replacement is the only correct call when the damage is severe. A compromised windshield simply won't provide the protection you need in a collision.

It’s time for a new windshield if:

The chip or crack is directly in the driver's field of vision.

A crack has spread to the edge of the windshield.

The damage is widespread, with multiple cracks or deep impact points.

The impact was strong enough to damage the inner layer of glass.

The market underscores just how vital this safety role is. Laminated glass accounts for a massive 45.18% of the 2024 revenue share in the impact-resistant glass market. This dominance is driven by its non-negotiable use in automotive windshields and buildings in storm-prone areas. You can dig deeper into the growth drivers in the impact-resistant glass market to see why its shatter-resistant properties are so critical.

The Modern Requirement: ADAS Recalibration

For newer vehicles, a windshield replacement has an extra, absolutely essential step: Advanced Driver-Assistance Systems (ADAS) recalibration. Your car’s safety features, like lane-keeping assist and automatic emergency braking, depend on cameras and sensors mounted directly to the windshield.

Installing a new windshield means these systems are no longer aimed correctly. They must be precisely recalibrated to factory specifications. Skipping this step isn't an option—it means your safety systems could fail when you need them most. Always make sure your auto glass shop has the right equipment to perform an ADAS recalibration for your specific vehicle.

Common Questions About Automotive Glass

Even after you know the basics of tempered and laminated glass, real-world questions always pop up. It’s one thing to understand how the glass is made, but it’s another to know what it means for your car, your wallet, and your safety. Let's tackle some of the most frequent questions I hear from vehicle owners.

Think of this as the practical side of things—the details that actually matter when you're dealing with a chip, a crack, or a shattered window. We'll get straight to the point on everything from telling the two types of glass apart to how the weather can affect them.

Is Laminated Glass Stronger Than Tempered Glass?

This is a classic question, and the answer isn't a simple yes or no. It really depends on how you define "stronger."

When it comes to resisting a single, blunt impact, tempered glass is technically the winner. Thanks to its intense heating and rapid cooling process, it builds up incredible surface tension. This makes it about four to five times stronger than regular annealed glass, meaning it can take a serious hit before it gives way.

However, if you're talking about security and holding up during a collision, laminated glass is in a league of its own. Its real strength isn't in resisting the initial crack—it's in what happens next. The tough PVB interlayer absorbs the force and stubbornly holds all the broken shards together. This makes it incredibly difficult for an object (or a person) to pass through.

The Bottom Line: Tempered glass is great at resisting breakage, but when it fails, it explodes into tiny pieces. Laminated glass may crack more easily, but it stays in one piece, which is crucial for keeping occupants inside the vehicle during a crash and for preventing break-ins.

So, while a stray baseball might just bounce off a tempered side window, a sharp tap from a rescue tool or a thief's center punch will make it disintegrate. That same blow to a laminated windshield would only create a spiderweb of cracks, with the glass remaining firmly in its frame. This is the key safety distinction that dictates where each type of glass is used.

How Can I Tell If My Car Windows Are Laminated?

Figuring out what kind of glass is in your car is actually pretty straightforward. We already know your windshield is laminated—that's been the law for decades. The real question is about your side and rear windows.

Here are a few ways to check:

Look for the "Bug": Every piece of automotive glass has a small stamp in the corner, often called a "bug." This label has manufacturer info and, most importantly, the glass type. It will often clearly state "Laminated" or "Tempered." Sometimes you'll just see a "T" or an "L."

Examine the Edge: Roll down your side window and look at the top edge. A laminated window will look like a sandwich—you'll see the two layers of glass with a very thin line of the PVB plastic between them. A tempered window will be a single, smooth sheet of glass from one side to the other.

Give It a Tap: This method is less scientific, but it often works. Tapping a tempered window with your knuckle usually produces a sharp, high-pitched "tink." Laminated glass, on the other hand, tends to make a duller, lower-pitched "thud" because the plastic interlayer dampens the sound.

Knowing what you have is becoming more important, especially as more luxury and high-end vehicles are now using laminated side glass for better sound insulation and added security.

Why Does My Windshield Get a Milky Edge?

That cloudy, hazy look creeping in from the edges of your windshield is a telltale sign of delamination. It happens when the adhesive bond holding the glass and the inner PVB layer together starts to break down. Once that seal is compromised, air and moisture can work their way in, creating that milky effect.

You'll see this most often on older cars or on vehicles where a poor windshield replacement job has damaged the seal. While it's not an immediate safety hazard if it's just on the very edge, it's a clear signal your windshield is nearing the end of its life. If that delamination starts spreading into your field of vision, it’s time for a replacement.

Can Extreme Temperatures Damage My Auto Glass?

Absolutely. Drastic and sudden temperature changes are the enemy of automotive glass. Pouring boiling water on a frozen windshield is the textbook example of what not to do—it's a surefire way to turn a tiny, invisible stone chip into a crack that runs clear across the glass.

The same principle applies in the summer. Blasting ice-cold A/C directly onto a windshield that’s been baking in the sun for hours can cause a stress fracture. Both tempered and laminated glass are built to handle normal seasonal shifts, but it’s the rapid-fire change that overloads the glass and causes existing weak points to fail.

Pro Tip: Always let your car's cabin temperature change gradually. On a frosty morning, use the defrost setting on a low fan speed to start. In the heat, let the A/C cool the cabin slowly instead of aiming the vents directly at the hot glass.

When you're dealing with any auto glass problem, from a small chip to a shattered window, professional service isn't just a good idea—it's critical for your safety. For drivers in the Bay Area, Auto Renu Auto Glass LLC provides expert mobile repairs and replacements that come to you. Whether you need a windshield replacement with ADAS recalibration or want to upgrade with professional window tinting, our team is committed to delivering dealership-quality results with the convenience you need. Visit us at https://www.autorenu911.com to get a fast, honest quote today.